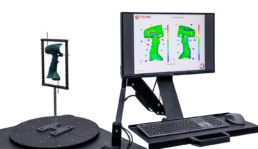

The solution for automated inspection tasks of any complexity

AUTOSCAN is a mobile inspection station equipped with a collaborative robot, a motorized rotation table, and powerful software. It helps capture quality information quickly and accurately through the laser-based SIMSCAN 3D scanner, enabling fast and reliable full surface measurement of parts. With the help of a collaborative robot and motorized table, the part can rotate and the scanner can be moved simultaneously to optimise scanning time and speed up the quality control process. Digitizing is completed in Eleven Dynamics planning and measurement software which can be integrated into a number of world-leading inspection platforms, including, Polyworks, Geomagic and Zeiss GOM Suite.

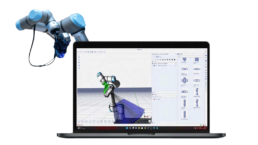

Easy Robot Programming in NEXUS from ELEVEN DYNAMICS

AUTOSCAN is programmed using the powerful open-source ELEVEN DYNAMICS Software. Utilising NEXUS 4.0, a virtual representation of the measurement area is created, which represents the complete measuring procedure. In the software, the CAD data set of the part to be inspected is imported along with the associated inspection plan. This is then used to automatically create the required robot paths to complete the measurement.

Software-based teaching allows the user to work remotely and send detailed and verified measurement plans to the factory. Measurement plans can be saved as templates so that measurements of repeat parts can be completed at the push of a button. This process can be locked, which enhances process control and reliability. With AUTOSCAN, detailed and complex inspection tasks can be easily delegated from the inspection room to the production team.

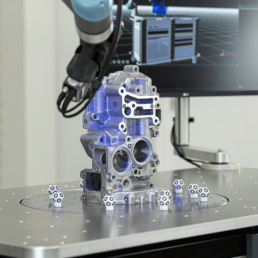

Field of Application

AUTOSCAN is driven towards robust and efficient quality control of small and medium-sized parts made of plastic, metal or cast iron. The system can be used in the inspection room or at-line, during the preproduction phase such as design and prototyping right the way through to full production where full inspection cycles are as short as just a few minutes.

Portable

Weighing less than 1kg, KSCAN Magic is lightweight and easy to manoeuvre. Its ergonomic soft grip makes 3D handheld scanning easy and comfortable