Reverse Engineering Service

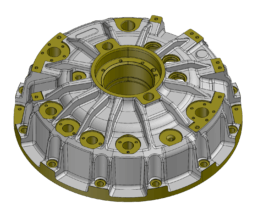

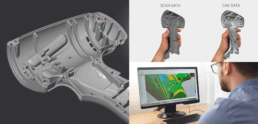

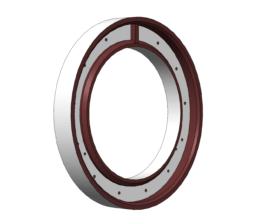

The most efficient way to generate a CAD model from a physical object that has any kind of complex or freeform shape is through a reverse engineering service.

Reverse Engineering: The Process

T3DMC have over 25 years experience in utilising 3D scan data for reverse engineering projects. We pride ourselves on producing highly accurate and reliable data for our customers.

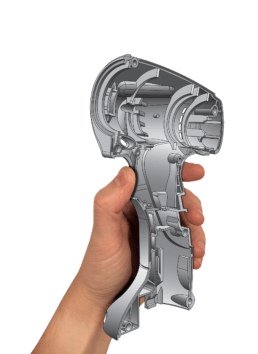

Parts can either be sent to us or collected by a member of our team at a convenient location. We then capture accurate full field 3D data using our blue laser scanners. The 3D scan data is then used by our engineers as a high detail guide to produce CAD surfaces.

We work across a range of software packages and can deliver parametric models with full design history, giving your team complete control over your own CAD with access to design parameters if there are redesigns required in the future. With our comprehensive range of 3D scanners and other measurement equipment, no part is too large or small.

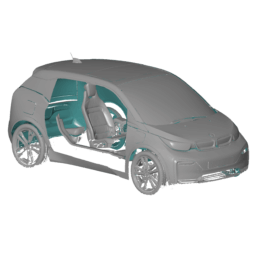

Initial Benchmarking

We analyse competitor components to help guide product development strategy.

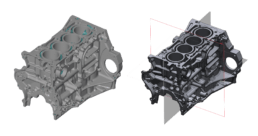

Redesign Outdated CAD

Achieve a highly accurate CAD, further developed and redesigned.

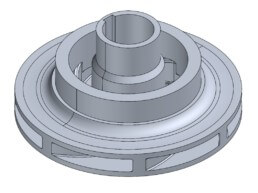

Repair and Replace

Take back control of your own parts through 3D models created from real part 3D scan data.

Digitally Archive Data

Digitally store data of your legacy components for future reference.

Our Team of Engineers Will Work With You

Whether improving an existing component through the use of 3D scan data, or measuring how effective your parts compare in your industry with Competitive Benchmarking, our reverse engineering service is here to help.

3D scanning for competitive benchmarking is a time-efficient and cost-effective way of keeping up with rapid advancements being made across an industry. The technology allows customers to gain a deeper understanding of why some competitor parts fail to help to avoid making the same mistakes themselves.

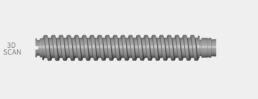

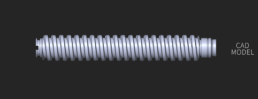

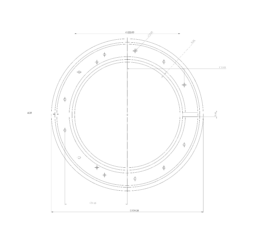

It is common place that a component will be developed and adjusted over time without the time taken to update the digital version from its original design intent. In these instances where a component has matured it is vital to update the CAD model to reflect the current as manufactured state of the component so that any future design decisions can be based on up to date CAD rather than historic models.

Now more than ever our customers have the requirement to source multiple suppliers of spare parts, either locally or internationally. T3DMC combine 3D scanning and data processing expertise to accurately capture the digital form of a component and create accurate parametric 3D CAD models and manufacturing drawings.

Historically, parts or tools no longer in use; prototypes, old model variants, crash test bodies etc were put into storage, taking up valuable operating space and adding significant cost to businesses. Digital archiving is the process of capturing accurate 3D surface data and reverse engineering that data in working, up-to-date as-manufactured CAD files which are then stored digitally and the original part or tool scrapped, bringing about huge cost savings through reuse of storage space and the improved work flows of having data stored digitally where it is easy to access and work from.