Value Engineering

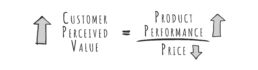

Design to Value, or value engineering, helps companies to understand precisely what their customers value about their products, offering solutions for delivering those valued features and capabilities at the lowest cost.

In recent years, for companies in wide range of industries, Value Engineering or Design to Value (DTV) methodologies have completely transformed the decision making processes around design, manufacturing, price and product positioning.

What is Value Engineering?

At its core, value engineering or design to value (DTV) is driven by getting more value for money – for companies and for their customers. It involves refining your designs and manufacturing processes to increase the functionality of your products while maintaining, or even reducing manufacturing costs. Value engineering uses clean sheet analysis to look at alternatives to your existing solutions. It can be practicably applied at any point of the product life cycle, but the most beneficial starting place is at the planning and design stage.

A key tool for these analyses techniques is 3D engineering; specifically 3D scanning and parametric computer aided drawing (CAD) creation which allow a comprehensive product Design to Value (DTV) assessment. This process yields increased understanding of product costs, increases profitability, improves competitive position and gives new infrastructure to procurement teams offering more control during cost negotiations with suppliers.

Through harnessing the full power of these innovative 3D engineering capabilities it is possible to enhance your own products and the T3DMC team of technical consultants are on hand to deliver this. With over 20 years industry experience in manufacturing, primarily in areas of product design and quality, T3DMC utilise a comprehensive 3D skills matrix across the UK and Asia to deliver in depth analysis, accurately and quickly so that decisions can be made without delay. With a targeted focus on cost efficient delivery of product specifications, our experience is drawn from developing cost engineering functions at a number automotive, consumer goods, packaging and tech companies as well as from completing in-house DTV analysis on our product lines.

It is clear that finding the most cost effective way to deliver a product or service is through an iterative process whereby design, manufacturing processes and suppliers are refined by repeating 3 fundamental steps:

Cleansheet cost modelling.

Comprehensive bottom up analysis; material, labour, overheads and equipment. All reviewed extensively to identify and understand key cost drivers.

Cleansheet target costing.

‘Should Cost Analysis’ is completed on each individual component used within a product to determine a true manufacturing cost.

Cost Engineering.

Bringing actual cost closer to the established target cost through a application of the newly defined engineering, purchasing and supply chain principles.

Market Research and Cost Modelling

Step one on the cleansheeting exercise calls for creating a cost model of how the part is currently designed and manufactured. Once this step is completed we can move to comparing against competitive products.

Product Benchmarking

We complete product teardowns for our clients and their competitors which includes 3D scanning of full assemblies and its sub components. Through comparison of 3D datasets we are able to gain valuable valuable insights that are difficult, if not impossible, to achieve in any other way, helping to identify opportunities for design improvements and cost reductions.

Comprehensive Value Analysis

After gaining product information from teardown and subsequent 3D scanning, we provide a detailed value analysis which can be used to guide design and manufacturing process improvements. Everything from materials used, wall thickness, weight all the way through to packaging are assessed for inefficiencies.

Idea Generation Workshops

Proposals are considered and built to include a range of improvements including product design, material selection, supplier negotiation toolkits based off ‘should cost’ modelling, manufacturing processes and manufacturing locations.

Next Steps

Many companies find that the process of developing a strong cleansheet target costing and value engineering function is an integral stepping stone along the route towards comprehensive Design to Value capabilities.

To understand this in more detail and how it will help improve profitability of your own products, get in touch with our team of expert consultants to discuss your requirements.

The exhibit shows a cost analysis completed on an industrial manual rotation table.