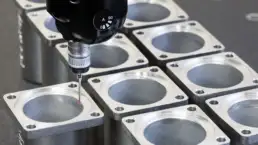

With a focus on reducing weight without compromising on durability, aluminium has become a pivotal material in the automotive manufacturing process. Its application extends to various automotive components such as engines, doors, hoods, all contributing to a significant reduction in the weight of vehicles.

The 6000-series alloy aluminium, which undergoes heat treatment to satisfy customer strength requirements, is the most prevalent material used in vehicles. When heat-treated, an aluminium alloy can surpass some steel grades in strength while maintaining its lightweight and malleability characteristics. However, the structural durability of aluminium components is often perceived as their most significant drawback. This necessitates meticulous inspections by manufacturers to guarantee that the parts fulfil stringent production requirements.

3D Analysis for Aluminium Castings in Automotive Applications

A company specialising in the production of lightweight metal components, services various industries including automobile manufacturing, 3C electronics, and aerospace among others.

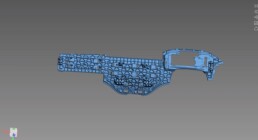

The client utilised Scantech’s handheld 3D scanner, SIMSCAN, to gauge the aluminium castings they produced. This enabled them to identify any deformities and make necessary adjustments based on the data acquired.

“Previously, we would dedicate an entire day to adjusting a single component. However, with Scantech’s 3D scanner, we’ve managed to decrease the time spent on measurement, inspection, and adjustment to just an hour. Not only that, but the portability of the 3D scanner allows us to evaluate more components, significantly increasing our efficiency and optimising our inspection workflow.”

The Solution: SIMSCAN 42