Streamlining Automotive Shop Floor Inspection

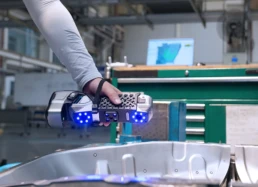

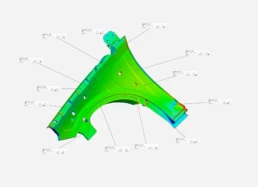

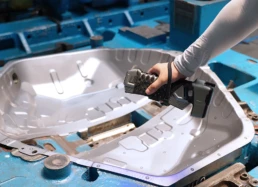

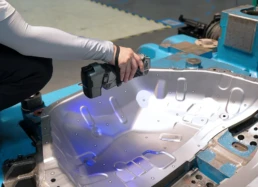

In the automotive manufacturing industry, stamping dies are foundational tools used to shape sheet metal into precise components that form the body structure of vehicles. These dies are instrumental in pressing or stamping operations that create complex shapes and features essential for automotive design and functionality. Given their critical role, the precision of stamping dies directly influences the quality and performance of the final products. Ensuring the accuracy and integrity of these dies is paramount, as even minor defects can lead to significant setbacks in production and compromise safety standards.