3D Design Software

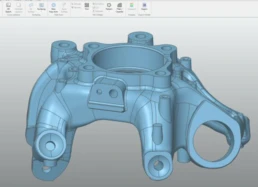

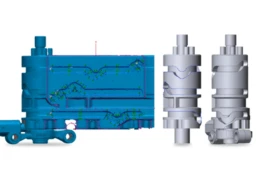

Geomagic Design X

Reverse Engineering Software

Geomagic Design X is a premier reverse engineering software that efficiently converts 3D scan data into feature-based, editable CAD models. Compatible with various 3D scanners, it serves industries like manufacturing and product design. The software enhances workflows with significant time and cost reductions, delivering CAD models faster than traditional methods. Geomagic Control X is a 3D software solution ideal for creating metrology-precision components and boosting operational efficiency across diverse applications.

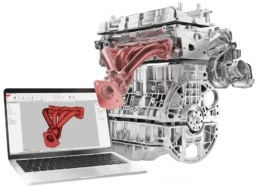

QUICKSURFACE

Reverse Engineering Software

QUICKSURFACE is a powerful reverse engineering software that converts 3D scan data into CAD models with high efficiency and precision. Compatible with various 3D scanners, it supports STL, OBJ, and PLY meshes, making it suitable for manufacturing and product design applications. The software offers hybrid modelling, interactive selection, and AI-powered tools, significantly reducing time and costs while enhancing design capabilities. It serves as a critical link between 3D scanning and manufacturing, providing an intuitive and cost-effective solution for precise reverse engineering.

Enhanced Production Accuracy

By converting detailed 3D scan data into precise CAD models, manufacturers can achieve higher accuracy in their production processes. This ensures that components fit together perfectly and function as intended, which is essential for maintaining high quality standards and reducing errors.

Reduced Lead Times

Reverse engineering software streamlines the design and prototyping phases by quickly transforming physical parts into digital models. This acceleration in the development cycle allows manufacturers to reduce lead times significantly, thus enabling faster time-to-market for new products.

Need Some More Information About Reverse Engineering Software?

Contact our team of metrology experts, get tailored advice for your specific design application

Benefits of Using Reverse Engineering Software

Legacy Part Replication

Many industries, such as aerospace and automotive, rely on maintaining or replacing outdated components. Reverse engineering software enables the replication of legacy parts that may no longer have available blueprints, ensuring the continued operation of older systems.

Streamline Time-to-Market

Reverse engineering shortens the product development cycle by quickly transforming existing products into digital formats ready for redesign and production. This rapid turnaround is vital for companies aiming to gain a competitive edge by launching new products faster.

Foster Innovation

By providing the tools to analyse and improve existing products, reverse engineering software encourages innovation. It allows designers to explore new possibilities and create advanced solutions, driving technological advancements across sectors like consumer products and aerospace.

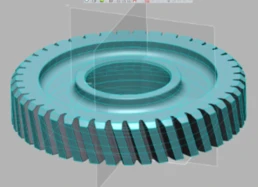

Improved Design Accuracy

Reverse engineering software accurately converts existing physical objects into detailed CAD models. This precision is critical for industries like manufacturing, automotive, and aerospace, where exact measurements are crucial for quality assurance and regulatory compliance.

Product Development

By enabling the creation of digital models from physical parts, reverse engineering allows for easier modifications and improvements. This accelerates the development of new products, facilitating innovation and enabling companies to meet changing consumer demands quickly.

Drive Down Cost

Reverse engineering software reduces the need for physical prototypes, saving on material costs and minimising waste. By allowing for digital testing and optimisation, companies can avoid expensive manufacturing errors and revisions.

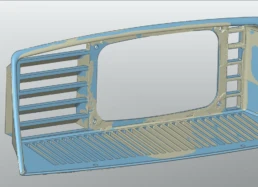

Enhancing Design Capability Across Industries

Automated inspection solutions propel success

Aeropace

In the aerospace sector, reverse engineering software is pivotal for maintaining and upgrading aircraft components. By generating precise CAD models, it ensures compliance with stringent safety standards and enhances performance. This technology enables the development of components that improve fuel efficiency and reduce weight, supporting sustainable aviation solutions. Reverse engineering helps aerospace companies efficiently meet high industry demands through accurate design replication and innovation.

Automotive

Reverse engineering software is crucial in the automotive industry for part optimisation and design innovation. It converts physical components into digital models, enhancing performance and reducing emissions. This technology is essential for replicating legacy parts, ensuring the maintenance of older vehicles. By exploring new design possibilities, reverse engineering keeps automotive companies at the forefront of technological advancements, driving product development forward.

Power Generation

In the power generation sector, reverse engineering software enhances equipment maintenance and efficiency. It allows for detailed analysis and optimisation of machinery, improving energy production and distribution. This technology supports sustainable energy solutions by redesigning components for renewable systems. By facilitating replication and improvement of critical parts, reverse engineering ensures reliable and efficient power generation, meeting global energy demands.

Contact Us

Need more information regarding design and reverse engineering software? Our team of 3D measurement experts are here to help.