3D Inspection Software

Zeiss Inspect

Inspection Software

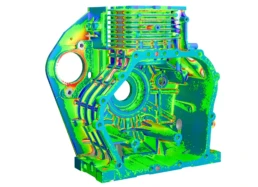

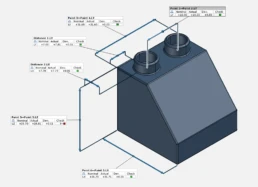

ZEISS INSPECT is a versatile metrology software designed to streamline the analysis of 3D, CT, and motion data, offering compatibility with various measurement systems to enhance efficiency and accuracy. With features like mesh editing, nominal-actual comparison, and customisable reporting, it provides a comprehensive solution for industrial inspection challenges, ensuring precise and reliable results.

PolyWorks Inspector

Inspection Software

PolyWorks|Inspector™ is a universal software platform that provides a comprehensive dimensional analysis and quality control toolbox, enabling seamless integration with all 3D measurement devices to enhance process control in product engineering and manufacturing. It offers powerful inspection capabilities, including parametric data handling, automated workflows, and advanced GD&T analysis, ensuring precise and efficient measurement processes across various industries.

Geomagic Control X

Inspection Software

Geomagic Control X is a leading metrology software that streamlines 3D scan data capture and processing, offering features like deviation analysis and trend analysis to enhance quality control and inspection. Integrated with 3D scanning technologies, it boosts inspection efficiency and cost savings, making it accessible for both experts and novices to improve manufacturing processes and product quality.

Need Some More Information About 3D Inspection Software?

Contacts our team of 3D measurement and inspection experts for tailored support on your specific requirements.

Benefits of Using 3D Inspection Software

Superior Quality Control

Continuous monitoring and real-time feedback ensure that products consistently meet high standards. The software supports stringent quality control processes, which enhances customer satisfaction and brand reputation.

Reduced Errors

By automatically identifying discrepancies from design specifications, the software minimises human error, leading to fewer production halts and less waste. This directly translates to smoother operations and more reliable output.

Significant Cost Savings

By enhancing precision and reducing errors, the software cuts down on material waste and labor costs. It also minimises the need for costly manual inspections, resulting in significant long-term savings for your business.

Seamless Integration

Our range of 3D inspection software integrates effortlessly with an array of measurement equipment, providing comprehensive analytics and reports. These insights drive continuous improvement, helping you optimise processes and maintain a competitive edge in the industry.

Enhanced Accuracy

3D inspection software offers unparalleled precision in measuring dimensions and geometries, ensuring that every component meets exact specifications. This level of accuracy reduces the likelihood of defects and reworks, ensuring superior product quality.

Improved Efficiency

With faster inspection times, the software accelerates the entire manufacturing process. It streamlines the workflow, allowing for more rapid decision-making and quicker time-to-market, which boosts overall productivity.

Enhancing Quality Assurance Across Industries

Automated inspection solutions propel success

Aeropace

In the aerospace industry, 3D inspection software is indispensable for ensuring safety and compliance with the sector’s rigorous standards. This technology allows for meticulous analysis of aircraft components, identifying even the slightest deviations that could compromise safety. By providing comprehensive inspection reports, aerospace companies can meet regulatory requirements while maintaining the highest safety standards.

Automotive

In the automotive industry, 3D inspection software plays a crucial role in enhancing precision during parts manufacturing and assembly. By utilising detailed digital scans and measurements, automotive manufacturers can ensure that each component aligns perfectly with stringent design specifications. This precision not only reduces the risk of costly recalls but also improves overall vehicle performance and safety.

Power Generation

Within the power and energy sector, 3D inspection software aids in maintaining equipment reliability and efficiency. It offers precise diagnostics of turbines, pipelines, and other critical infrastructure, helping to predict potential failures before they occur. This proactive approach minimises downtime and enhances operational efficiency, ensuring a steady and reliable energy supply.

Contact Us

Need more information regarding 3D Inspection software? Our team of engineers are ready to help.