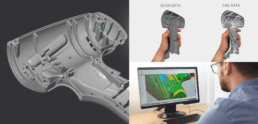

3D scanning brings significant benefits to reverse engineering projects where precise data is needed

As a leading provider of 3D scanning services and distributor of handheld portable laser scanners, T3DMC knows first-hand the benefits that this innovative technology can provide. 3D scanning is of undisputed value when it comes to quality and inspection, as well as product and competitor benchmarking, but 3D scanning is also an invaluable tool for reverse engineering projects, where it can simplify and speed up the entire process – here’s how.

Reverse engineering is a process which aims to make it possible to reconstruct an object or component for which the original design data is not available. There are many reasons for wanting to do this – think about re-manufacturing an obsolete component, a fragile object with considerable wear and tear, or a unique historical artefact. In such instances, traditional measurement techniques are difficult and time consuming, especially for objects where handling must be limited. 3D scanning, which is a rapid non-contact method of gathering dimensional data, solves these problems.

Full data for precision engineering

Further, in the past, components or tools that were no longer in use, prototypes, old model variants, crash test bodies and so many other artefacts potentially important to a business, had to be carefully stored for future reference, taking up precious space. But thanks to 3D scanning, it’s now possible to replace the artefacts themselves with digital archives in the form of comprehensive and highly detailed, three-dimensional CAD files.

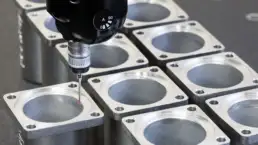

3D scanning brings significant benefits to reverse engineering projects where precise data is needed, down to micron levels. It is a fast and extremely accurate method of creating a full data report for a given object, as it quickly captures even the most complex geometry and thanks to the comprehensive range of 3D scanners and other in-house measurement systems in use at T3DMC, no item is too large or too small to be scanned.

3D scanning for reverse enginering

Once an object is scanned, the 3D data can be used to create a mesh model by connecting the scanned data points in a point cloud. The mesh model provides the base structure for developing a CAD model which can be used to replicate the original component or artefact, or as an aid to making design improvements. When the aim of a project is to enhance the source object, any damage, errors or structural features that negatively affect it, can easily be changed to improve performance. Conversely, if there’s a requirement for an “as is” representation of the original scanned part, this can also be provided.

3D scanning for reverse engineering projects can also help users to gain a deeper understanding of why some parts fail and to identify weaknesses in their design or manufacturing processes, thereby making a major contribution to on-going product improvement.