PolyWorks® Software

At T3DMC, we are proud to leverage the power of PolyWorks® software to deliver precise and reliable 3D measurement solutions. As a leading platform in the metrology industry, PolyWorks® seamlessly integrates with advanced scanning and probing technologies, providing accurate and efficient data processing for a wide range of applications.

Why Choose PolyWorks®?

PolyWorks® software is trusted worldwide for its ability to streamline the entire 3D measurement process. Here’s why it stands out:

- Comprehensive Data Management: Supports large datasets and complex geometries.

- Integration Flexibility: Works seamlessly with various scanning and probing hardware.

- Advanced Analysis Tools: Delivers precise inspection reports and actionable insights.

- User-Friendly Interface: Intuitive controls for enhanced productivity.

- Customisation Options: Tailor workflows to meet specific project needs.

T3DMC and PolyWorks® Integration

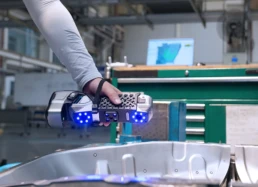

Our team at T3DMC harnesses PolyWorks® to optimise inspection processes and ensure data accuracy. We integrate the software with our cutting-edge scanning equipment, enabling:

- Real-time visualisation of measured data.

- Automated inspection routines for consistent quality control.

- Detailed reporting with visual comparisons and deviations.

- Enhanced efficiency through data integration and processing.

Need more information about PolyWorks® ?

Contacts our experts for tailored support on your specific requirements.

Applications of PolyWorks®

PolyWorks|Inspector™ is a universal software platform that provides a comprehensive dimensional analysis and quality control toolbox, enabling seamless integration with all 3D measurement devices to enhance process control in product engineering and manufacturing. It offers powerful inspection capabilities, including parametric data handling, automated workflows, and advanced GD&T analysis, ensuring precise and efficient measurement processes across various industries.

Aeropace

In the aerospace industry, 3D inspection software is indispensable for ensuring safety and compliance with the sector’s rigorous standards. This technology allows for meticulous analysis of aircraft components, identifying even the slightest deviations that could compromise safety. By providing comprehensive inspection reports, aerospace companies can meet regulatory requirements while maintaining the highest safety standards.

Automotive

In the automotive industry, 3D inspection software plays a crucial role in enhancing precision during parts manufacturing and assembly. By utilising detailed digital scans and measurements, automotive manufacturers can ensure that each component aligns perfectly with stringent design specifications. This precision not only reduces the risk of costly recalls but also improves overall vehicle performance and safety.

Power Generation

Within the power and energy sector, 3D inspection software aids in maintaining equipment reliability and efficiency. It offers precise diagnostics of turbines, pipelines, and other critical infrastructure, helping to predict potential failures before they occur. This proactive approach minimises downtime and enhances operational efficiency, ensuring a steady and reliable energy supply.