We first introduced this pioneering effort on the T3DMC blog back in October 2024. Now, we’re revisiting the story to share how the journey has evolved and to provide the latest updates on this ambitious build.

The Vision148 project is redefining automotive restoration by merging classic design with cutting-edge digital technology. At its heart is a legendary vehicle: the Ford Sierra Cosworth RS500, specifically chassis #148 of the original 500 produced. This ambitious initiative, named the “Carbon Piranha,” aims to recycle, reimagine, and rebuild the car, creating a one-of-a-kind masterpiece that showcases the future of manufacturing while honouring its heritage. We’ll be outlining the journey so far, from initial concept to its current phase of high-tech revival.

The project’s foundation is a collaborative effort between industry leaders, with T3DMC playing a pivotal role in its success. Known for cutting-edge advancements in digital manufacturing, T3DMC brings unparalleled expertise to the table, ensuring precision and efficiency throughout the process. From the initial teardown to the final powertrain calibration, Vision148 represents a symphony of artisan skill, digital precision, and T3DMC’s innovative contributions to push the boundaries of quality and innovation.

The Genesis: Deconstruction and Digital Twinning

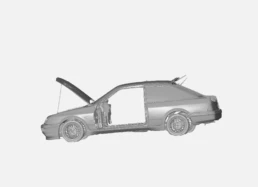

The journey began with the careful disassembly of the donor RS500 by ASM Auto Recycling, a leader in vehicle dismantling and recycled parts supply. Every component was meticulously categorised, setting the stage for the next critical phase: digital replication. This is where T3DMC, specialists in advanced 3D scanning, stepped in.

Using state-of-the-art metrology equipment, our team captured the exact geometry of each part. This process created a precise “digital twin” of the vehicle – a virtual blueprint that serves as the foundation for the entire reimagination and rebuild process. This digital model allows engineers and designers to analyse, modify, and perfect components in a virtual environment before any physical manufacturing begins.

The Reimagination: Design Meets Engineering

With a complete digital twin established, the creative phase commenced. Renowned visualisation artist Yasid Design took the lead, collaborating with engineering partners to conceptualise the Carbon Piranha. The goal was not simply to restore the car but to enhance it, integrating modern aerodynamics, advanced materials, and a contemporary aesthetic while preserving the soul of the original RS500.

This reimagination phase is a testament to the power of digital design. It allowed the team to experiment with new forms and functions, ensuring the final vehicle would be both visually stunning and performance-oriented.

The Rebuild: Additive Manufacturing and Artisan Skill

The physical rebuild is being spearheaded by the Digital Manufacturing Centre (DMC) at Silverstone. The DMC is leveraging its expertise in additive manufacturing—also known as 3D printing—to produce bespoke components for the vehicle. This technology enables the creation of complex, lightweight, and incredibly strong parts that would be impossible to fabricate using traditional methods.

At the core of this high-tech build is the powertrain. Official partner Cosworth, the brand intrinsically linked to the car’s original success, is central to the engine’s revival. Their involvement ensures the Carbon Piranha will possess the exhilarating performance credentials that made the RS500 a motorsport legend. This fusion of advanced manufacturing from the DMC and powertrain expertise from Cosworth highlights the project’s unique blend of heritage and innovation.

A Project for the Fans: The Autovision.club

Vision148 is more than just a car build; it is an interactive experience. The Autovision.club offers members intimate access to the project’s progress. Through a unique points-based system, the club rewards engagement and provides a direct line to the build team. Ultimately, this ground-breaking membership model will culminate in one dedicated fan winning the completed, one-of-one Carbon Piranha.

This approach transforms the project from a private restoration into a community-driven journey, allowing enthusiasts to be part of automotive history. Vision148 also supports Race Against Dementia, adding a philanthropic mission to accelerate research for preventions and cures.

The Journey Continues...

As the Vision148 project moves forward, it continues to serve as a powerful case study for the integration of digital manufacturing solutions in the automotive sector. The collaboration between T3DMC, Cosworth, the DMC, and other key partners demonstrates how modern technology can elevate artisan craftsmanship to new heights. The journey of the Carbon Piranha is far from over, and it stands as a bold statement on the future of bespoke vehicle creation.

Why Choose 3D Scanning for Your Automotive Project?

The adoption of 3D scanning brings demonstrable value to automotive projects, offering enhanced accuracy, reduced development times, and lower costs.

- Value Proposition:

- Increased precision and design optimisation.

- Expedience in R&D and product development.

- Cost savings and minimised waste.

Interested in leveraging 3D scanning for your automotive project?

Reach out to T3DMC for expert advice and customised solutions tailored to your needs.