Unlocking the Potential with Reverse Engineering and CAD Modelling

At T3DMC, we take pride in offering top-tier reverse engineering and CAD modelling services, combining our extensive industry knowledge with cutting-edge technology to deliver exceptional results. Let’s delve into what makes reverse engineering and CAD modelling indispensable in today’s digital manufacturing landscape and why T3DMC is your go-to partner for these services.

What Is Reverse Engineering?

Reverse engineering is a transformative process that allows businesses to recreate accurate digital models from existing physical parts, a capability that is invaluable across several industries.

In the automotive sector, reverse engineering is extensively used to recreate components for vintage vehicles where original parts are no longer available. By utilising reverse engineering CAD software, manufacturers can produce exact replicas of obsolete parts, ensuring the longevity of classic cars.

In the aerospace industry, reverse engineering plays a crucial role in maintaining and upgrading aircraft. It enables the creation of precise 3D reverse engineering models of complex components, ensuring that replacement parts meet stringent safety and performance standards.

For the broader manufacturing industry, reverse engineering is essential for optimising product designs and enhancing performance. Companies can analyse competitor products to understand their design and manufacturing techniques, paving the way for innovation and improved performance. This process also facilitates the customisation of existing products to better meet specific consumer needs. By integrating advanced 3D scanning and CAD modelling technologies, reverse engineering empowers industries to innovate and excel, driving efficiency and enhancing product offerings.

Advantages of Reverse Engineering

Reverse engineering offers a multitude of benefits that extend well beyond merely replicating existing parts. One of the primary advantages of reverse engineering is its ability to breathe new life into legacy systems by recreating precise, functional designs when original documentation is unavailable. By employing reverse engineering CAD software, businesses can reconstruct complex structures and refine designs, leading to enhanced innovation and product development. This method is instrumental in competitive market analysis, allowing companies to dissect competitor products and integrate superior design elements into their own offerings. Furthermore, reverse engineering CAD drawings provide a robust framework for modifications and customisations, enabling tailored solutions that meet specific customer requirements. Overall, 3D reverse engineering facilitates a deeper understanding of product functionality and design intent, driving strategic improvements and sustained innovation.

The Role of 3D Scanning and CAD Modelling

3D scanning is pivotal in the reverse engineering process, offering superior precision and efficiency compared to traditional measurement techniques. With reverse engineering CAD modelling, 3D scanning captures the complete geometry of an object, including intricate details often missed by traditional measurement methods. This advanced technology utilises laser scan to CAD model conversions, creating highly accurate digital meshes that serve as the foundation for detailed CAD models. The reverse engineering scan to CAD process is streamlined, reducing the time and potential errors associated with manual data collection. By integrating cutting-edge 3D scanning with reverse engineering CAD software, businesses can achieve unparalleled accuracy and data fidelity, essential for high-stakes applications in quality control, prototyping, and product development. This synergy not only accelerates project timelines but also empowers engineers to push the boundaries of innovation, ensuring that every model reflects the highest standards of precision and reliability.

How 3D Scanning and Modelling is Executed

Our expert team employs advanced reverse engineering CAD software to transform digital mesh data into precise CAD models. This process ensures every detail is captured accurately, optimising the reverse engineering scan to CAD workflow. Whether dealing with small components or large structures, our tailored approach guarantees high-quality outcomes.

How 3D Scanning and Modelling is Executed

With over 20 years of experience, T3DMC’s team advises on the most suitable 3D scanning equipment based on the part’s size, material, and complexity. Our reverse engineering CAD process is not one-size-fits-all; each project is customised to deliver the best results, from simple CAD files to complex parametric models.

Driving Innovation with Reverse Engineering

Embracing the benefits of reverse engineering and CAD modelling empowers businesses to push boundaries and enhance efficiency. By leveraging advanced 3D reverse engineering techniques and comprehensive CAD solutions, T3DMC helps you transform engineering challenges into opportunities for growth. Contact us today to explore how these cutting-edge services can revolutionise your manufacturing processes.

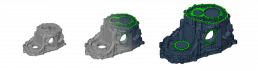

This is the process of reverse engineering from CAD but taking into account original design decisions in an effort to get the CAD into a condition that more closely resembles the original intended design. Rather than the modified or work altered part that was scanned, here we are able to create fully parametric CAD models with geometric constraints based on design consultation with the customer.

We are able to make experience-driven decisions of what certain geometries should be and where necessary we will deviate away from the scan geometry and manually drive these elements within the model. All done through consultation with the customer.

Recent news posts

Contact Us

Got any questions about reverse engineering? Contact us today, our team are ready to assist.