Precision and Efficiency in the Automotive Industry with 3D Scanning

The automotive industry is rapidly evolving, driven by the demand for increased precision and efficiency. To remain competitive, automotive manufacturers and engineers seek innovative solutions to optimise design and manufacturing processes. One such solution is 3D scanning, which has become an essential tool in achieving accuracy and streamlining operations. Whether you are an automotive manufacturer, engineer, aftermarket developer, or quality assurance specialist, incorporating 3D scanning into your workflow can offer substantial benefits.

What is 3D Scanning?

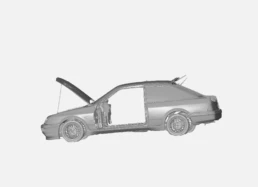

3D scanning is a non-contact, non-destructive technology that captures the shape of physical objects using a line of laser light. It creates a digital 3-dimensional representation, allowing for in-depth analysis and manipulation. Traditionally used in engineering and design, 3D scanning now finds extensive applications in the automotive industry.

Key Benefits for Automotive Applications

Enhanced Accuracy: 3D scanning offers high precision in capturing intricate details, crucial for engineering and design work.

Faster Project Timelines: Typical workflows are accelerated, reducing overall time-to-market.

Reduced Material Waste: By optimising component designs, waste is minimised, contributing to cost savings and sustainability.

Improved Reverse Engineering and Prototyping: Engineers can easily reverse-engineer existing products or develop prototypes, maintaining quality throughout.

Key Applications of 3D Scanning in the Automotive Industry

Benchmarking for Automotive Optimisation

3D scanning plays a crucial role in automotive benchmarking by offering precise, high-resolution data that allows engineers to compare vehicle components against competitors or prototypes. Through 3D surface scans, manufacturers can analyse geometries, reverse engineer designs, and evaluate material thickness and uniformity. This data provides valuable insights that help identify areas for improvement, such as design innovations or manufacturing efficiencies found in competitor models.

The benefits of 3D scanning in benchmarking are significant, as it enhances component design, optimises material selection, and boosts overall vehicle performance. For instance, engineers can refine suspension systems or aerodynamics based on competitor insights while ensuring materials achieve the ideal balance between weight and durability. Additionally, the speed and accuracy of 3D scanning streamline the R&D process, reducing time-to-market and improving cost-efficiency.

Real-world applications include analysing electric vehicle battery placements, optimising prototype designs, and refining safety features like crumple zones. Companies like T3DMC provide essential support for these processes with advanced portable and stationary 3D scanning solutions. Their expertise ensures manufacturers can benchmark effectively, relying on detailed data to innovate and maintain a competitive edge in the industry.

Accelerating Aftermarket Product Development

3D scanning has revolutionised aftermarket automotive product development by providing precise digital models of vehicles or components. This technology is essential for creating custom body kits, interior accessories, and protective films that align perfectly with a vehicle’s specifications. By capturing accurate measurements and surface details, 3D scanning ensures seamless fits and enhances both product functionality and appearance. This digital approach eliminates the need for time-consuming manual measurements, providing a more efficient workflow for aftermarket manufacturers.

Reverse engineering tools like GeoMagic Design X and SolidWorks play a crucial role in leveraging 3D scans for aftermarket development. Once a component is scanned, developers can import the data into these software platforms to refine designs, adapt them for production, or make personalised modifications. For example, custom body kits are designed to match the exact contours of a vehicle’s exterior, while interior accessories like tailored seat covers and dashboards are created with precise geometries. Protective films also benefit, as scanning ensures templates align with complex vehicle surfaces, achieving maximum coverage with minimal waste.

The advantages of 3D scanning in this field are significant, including greater design accuracy, shorter development cycles, and reduced material waste. By enabling virtual testing of designs, 3D scanning minimises physical prototyping needs, cutting both costs and production timelines. Real-world applications include producing aerodynamic body kits for performance vehicles, restoring vintage car interiors with custom parts, and designing flawless protective films for high-end models. This technology has become a game-changer in delivering high-quality aftermarket products quickly and efficiently.