“T3DMC has helped us by analysing the geometry of our components and making recommendations for tooling improvements, and this has saved us a lot of time over the years”.

BorgWarner is an automotive components manufacturer dedicated to supporting its customers in their quest for clean propulsion and efficient technologies. The company works with OEMs producing passenger cars, marine equipment, heavy-duty vehicles, and vehicles for off-highway applications.

Numbering among those customers such high-profile names as Scania and Volvo, BorgWarner is committed to meeting and maintaining the highest standards of quality and performance. To help BorgWarner meet this commitment, T3DMC has been collaborating with the company for almost a decade providing our 3D scanning service and 3D and measurement, quality analyses and benchmarking reports.

“Our main challenge is performance replication, because a small deviation from design intent in a performance critical component can result in unacceptably large performance changes at system level” says Hanif Khan, Staff Engineer at BorgWarner.

“T3DMC has helped us by analysing the geometry of our components and making recommendations for tooling improvements, and this has saved us a lot of time over the years”.

Boosting Performance with 3D Scan Data

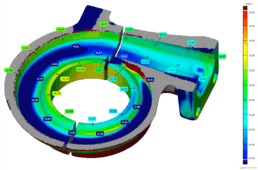

A recent project T3DMC has been involved in is 3D scanning the volute surfaces of a turbocharger, which is used to boost engine performance on vehicles. BorgWarner’s dual volute turbine allows complete segregation of exhaust pulsations, which means that the turbine can use a larger proportion of the exhaust gas pulse energy, thereby operating more efficiently.

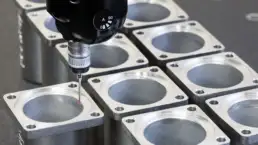

“Our key role is to find out whether components from the production line accurately match the design intent”, explains Neal Taylor, Technical Director at T3DMC.

“We first scan the components internally and externally in our temperature stable measurement room. After that we work with section property measurements to create an analysis that BorgWarner uses to inform tooling changes and product optimisations.”