“T3DMC carried out 3D scans of specific areas of the car body work and from there, produced designs for all components, with only a handful of photos of the original car.”

Bridgnorth-based Classic Motor Cars (CMC) is an award winning company that specialises in restoration of classic cars and motorbikes to optimum performance and world-class safety standards. The company acquired a one-of-a-kind Jaguar XK120 SE, restyled by the legendary Italian designer Pininfarina, but as it often happens with such treasures, the car was in pretty bad shape and extensive restoration work was needed. With little reference material to accompany the project, CMC called in T3DMC to help restore some of the vehicle’s historical features.

The Pininfarina Jaguar was originally purchased by an automobile collector in the USA and had remained overseas until recently. Sensing that this was a once in a lifetime opportunity, CMC bought the car and brought it to its Bridgnorth workshop. The team then embarked on a lengthy restoration journey that was meant to bring the vehicle back to its original specification and design.

The restoration was challenging due to a lack of information about the original specification of the car, as parts were missing or had been severely damaged. The only thing the team had to go by were three grainy photos of the car in its heyday.

There were several significant areas of the restoration that the Classic Motor Cars team needed specialist help with, so they called upon the expert engineers at T3DMC to use their market leading 3D optical scanning equipment to scan the rear screen opening and front and rear panels to capture a 3D digital model of the vehicle.

“One of the main difficulties for us was the acquisition of a number of missing parts and it was here that the assistance of T3DMC came in handy”, explained Finn Walton, engineer at CMC.

“We needed to recreate front and rear side-light units and a replacement for the rear windscreen. T3DMC carried out 3D scans of specific areas of the car body work and from there, produced designs for all components, with only a handful of photos of the original car.”

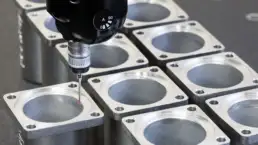

T3DMC then used the output of the 3D optical scanning process, along with the three remaining original photos of the vehicle to create digital CAD models. Reverse engineering and rapid prototyping equipment were then used to generate representations of the front and rear lights.

The test fit showed where additional design modifications required, and further prototypes were produced to make sure the model was exactly as it should be. The CAD model was subsequently finalised and fed into industrial CNC and 3D printing machines to generate the final parts.

The 3D optical scan data was also used to reproduce the entire front end of the car and the rear window was recreated at a speciality glass manufacturer to complete the restoration project.

“When fully satisfied with the designs and fit, T3DMC helped source and enlist manufacturers who could complete the supply chain and provide CMC with what was effectively a finished product”, added Finn. “The final manufacturing process included high accuracy 3D printing of some components in specific materials that were suitable for chrome plating, and the subsequent plating of those parts and CNC machining and polishing of Perspex resulted in the stunning new lenses and reflectors you can now see on the vehicle”.

Much of the work carried out was a new venture for both CMC and T3DMC and the quality of the finished items was of the utmost importance considering the significance of the car and that its first outing and unveiling would be at the renowned Pebble Beach Concours D’Elegance in California, USA.

“Suffice to say we were extremely happy with the results and all work was carried out and completed within a very tight timescale”, explained Finn. “Communication was excellent throughout the process and this was aided hugely by the close proximity of T3DMC’s premises to our own. It was a real pleasure to work with a small local business leader, working in a new field for them to help in the restoration of a 60 year old car. These design and production methods are sure to become far more common place in the restoration industry in the future, but we are proud to have been able to work with T3DMC in showing the world what is achievable, and we look forward to working with them again when a project requires something a bit special or out of the ordinary”, concluded Finn.

Classic Motor Cars invested nearly 8,000 man hours into the restoration, and the T3DMC team contributed significantly to the success of the project, as without the missing parts, it would have been impossible to complete.

The restored Jaguar went on to win ‘Restoration of the Year’ at the 2017 Octane Awards and came second in its class at the Concours d’Elegance which is one of the most prestigious car shows in the world hosted annually at Pebble Beach, California.

“This is a great example of modern 3D optical scanning, 3D CAD design and reverse engineering being used to help recreate a timeless classic vehicle and we are very proud to be involved”, concluded Adam Stanley, Managing Director at T3DMC. “It gives us the confidence to tackle automotive projects, irrespective of their level of complexity”

If you are working on a restoration project or have the need for our 3D optical scanning or reverse engineering capability, please contact us on info@t3dmc.com or give us a call on 01746 762251 and we will be delighted to try to help you with a 3D engineered solution.

Other news articles