Exploring the Benefits of 3D Scanning: Transforming Industries and Innovation

In the fast-paced world of technology, 3D scanning has emerged as a revolutionary tool that is driving innovation across various fields. This technology allows for the precise capture of the shape and appearance of objects, paving the way for new methods in design, production, and analysis. In this article, we will delve into the fundamentals of 3D scanning technology, its impact on different industries, its numerous benefits, and what the future holds.

Understanding 3D Scanning Technology

At its core, 3D scanning is a process that digitises physical objects into virtual 3D models. This is achieved through various methods, which can vary in complexity and application. The scanned data can then be used for different purposes, including manufacturing, simulation, and visualisation.

The Basics of 3D Scanning

3D scanning works by using various technologies such as laser scanning, structured light scanning, and photogrammetry. These technologies collect data points from the surface of the object being scanned.

Laser scanning is one of the most common methods, employing laser beams to measure and collect distances between the scanner and the object. This creates a cloud of points that represents the object’s outer shape. On the other hand, structured light scanning projects light patterns onto the object, capturing the distortion of these patterns to create a 3D representation. Each method has its own advantages; for instance, laser scanning is particularly effective for large-scale objects and complex geometries, while structured light scanning is often preferred for smaller, intricate details due to its high resolution.

The Evolution of 3D Scanning

The origins of 3D scanning date back several decades, initially utilised for industrial applications. Over time, it has evolved to embrace advancements in computing power and software capabilities, allowing for increased accuracy and efficiency.

As technology progressed, 3D scanning transcended its industrial roots and started to find applications in various fields, including art conservation, architecture, archaeology, and even fashion. Today, it plays an integral role in the seamless merging of the physical and digital worlds. For example, in the realm of art conservation, 3D scanning allows curators to create detailed records of sculptures and artefacts, enabling restoration efforts that are both precise and respectful of the original work. Similarly, in architecture, 3D scans can capture the intricate details of historical buildings, providing architects and planners with invaluable data for renovation projects or new constructions that harmonise with their surroundings.

The Impact of 3D Scanning on Various Industries

3D scanning technology has significantly altered how industries operate. Its integration has led to enhanced processes, improved product design, and cost-effective methods of operation.

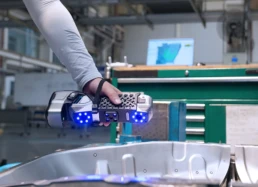

3D Scanning in Manufacturing

In manufacturing, 3D scanning has streamlined the production process by ensuring accuracy and reducing errors. Factories are now using scanners to create digital twins of products, which allows for real-time monitoring and adjustments.

This precision not only translates to higher quality products but also decreases waste and optimises resource allocation. Ultimately, this boosts the bottom line while maintaining high standards. Moreover, the ability to quickly iterate on designs through 3D scanning allows manufacturers to respond more swiftly to market demands, fostering innovation and adaptability in an ever-evolving landscape.

The Role of 3D Scanning in Healthcare

The healthcare industry has also reaped the benefits of 3D scanning technology. It is increasingly used in fields such as orthopaedics and dentistry, where custom implants and prosthetics are vital.

By creating accurate 3D models of patient anatomy, healthcare professionals can design and produce personalised solutions that meet specific needs, resulting in better patient outcomes. Additionally, 3D scanning facilitates pre-surgical planning, allowing surgeons to visualise complex cases and rehearse procedures, which can significantly reduce operation times and improve overall surgical precision.

3D Scanning in the Entertainment Industry

The entertainment industry has witnessed a digital revolution, with 3D scanning playing a crucial role in enhancing visual effects and animation. By scanning real-world objects and environments, creators can produce hyper-realistic representations in movies and video games.

This technology not only improves the quality of cinematic experiences but also opens new avenues for storytelling and artistic expression. Furthermore, the use of 3D scanning in virtual reality (VR) and augmented reality (AR) applications has transformed how audiences engage with content, allowing for immersive experiences that blur the lines between the digital and physical worlds. As a result, filmmakers and game developers are continually exploring innovative ways to leverage this technology, pushing the boundaries of creativity and audience interaction.

The Benefits of 3D Scanning

As industries have adopted 3D scanning technology, its benefits have become increasingly evident. These include enhanced precision, significant time savings, and the ability to customise products to suit individual needs.

Enhancing Precision and Accuracy

One of the primary advantages of 3D scanning is its capacity to create highly accurate digital representations of physical objects. This precision minimises the risk of errors during design and manufacturing processes, ensuring that the end products meet the required specifications.

With improved accuracy, businesses can deliver high-quality products that meet both customer expectations and industry standards. For instance, in the aerospace sector, where even the slightest deviation can lead to catastrophic failures, 3D scanning has become indispensable. It allows for the meticulous inspection of components, ensuring that every piece fits perfectly within complex assemblies. This level of detail not only enhances safety but also boosts confidence in the reliability of the final product.

Saving Time and Resources

3D scanning expedites the design and manufacturing process by enabling rapid prototyping. Instead of lengthy iterations on physical models, designers can quickly create, test, and modify digital versions.

This not only reduces the time from concept to production but also ensures that resources are utilised more efficiently, leading to cost savings for companies. Additionally, the integration of 3D scanning with other technologies, such as additive manufacturing, allows for a seamless transition from digital designs to physical objects. This synergy not only accelerates production timelines but also opens up possibilities for innovative designs that were previously deemed impractical or too costly to produce.

Facilitating Customisation and Personalisation

In today’s market, consumer preferences lean heavily toward customisation. Whether in fashion, automotive, or healthcare, 3D scanning allows companies to produce tailored products that suit the unique requirements of individuals.

By capturing precise measurements and details, businesses can deliver solutions that enhance user experiences and satisfaction. For example, in the healthcare industry, 3D scanning is revolutionising the creation of prosthetics and orthotics. Custom-fitted devices that are designed based on the patient’s unique anatomy not only improve comfort but also enhance functionality. This level of personalisation extends to industries like fashion, where designers can create bespoke clothing that perfectly matches the wearer’s dimensions, thus elevating the overall appeal and marketability of their products.

The Future of 3D Scanning

The future prospects of 3D scanning technology are promising, with numerous emerging trends indicating further growth and innovation. Industries are continuously looking for ways to leverage this technology to stay competitive.

Emerging Trends in 3D Scanning

New developments in artificial intelligence and machine learning are paving the way for more sophisticated 3D scanning solutions. Automated scanning processes are expected to improve accuracy and efficiency dramatically.

Additionally, as mobile devices become more powerful, portable scanning solutions are making 3D scanning accessible to a wider range of users and applications. This democratisation of technology is not only beneficial for small businesses and individual creators but also opens doors for educational institutions to incorporate 3D scanning into their curricula. Students can engage with hands-on projects that enhance their understanding of design and engineering principles, preparing them for future careers in a tech-driven landscape.

The Role of 3D Scanning in Sustainable Development

An area where 3D scanning can make a notable impact is in sustainable development. By enabling precise measurements and analyses, the technology helps in resource optimisation and waste reduction.

Additionally, it plays a crucial role in various environmental studies, allowing for the monitoring of ecosystems and the restoration of habitats. The future of 3D scanning could very well be intertwined with sustainable practices, promoting innovation in a way that benefits both industries and the planet. For instance, in construction, 3D scanning can facilitate the design of energy-efficient buildings by providing accurate data on materials and spatial configurations. This not only reduces the carbon footprint of new developments but also encourages the use of recycled materials and sustainable practices in the building process.

Furthermore, the application of 3D scanning in agriculture is gaining traction, where it can be used to assess crop health and optimise land use. By analysing the topography and soil conditions, farmers can make informed decisions that enhance yield while minimising environmental impact. As these applications expand, the synergy between technology and sustainability will likely lead to innovative solutions that address some of the most pressing challenges of our time.