UMA Smart Desktop

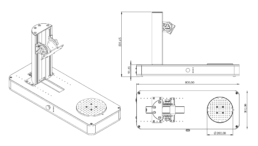

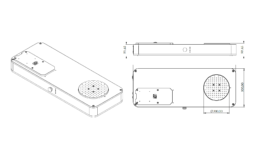

The Smart Desktop offers a comprehensive solution for small parts inspection, including a choice between a robot/tower setup, sensor, rotary table, and an optional workstation.

Each model of the Smart Desktop is designed to work seamlessly with an extensive range of 3D scanners and 2D sensors, allowing for customisation into an optical Coordinate Measuring Machine (CMM) or a visual inspection system.

Simple Software

The Streamline software offers a user-friendly interface that integrates seamlessly with all hardware components.

Rapid Performance

Featuring integration with our range of Scantech 3D scanners, this station boasts quicker cycle times than any competing system.

Efficient Investment

Offering the high productivity at the lowest cost in comparison to any other automated metrology solution.

Powered By Streamline

There’s no need for a dedicated robot programmer; the Streamline software offers a user-friendly interface that integrates seamlessly with all hardware components.

Get In Touch

Contact our team of experts today, they will work with you to find the optimal solution for your projects.

Smart Desktop Technical Specification

| Type | Tower Version | Robotic Version | ||

|---|---|---|---|---|

| Base Dimensions | (WxDxH) | 800 x 300 x 91 mm | 800 x 300 x 91 mm | |

| Full Product Dimensions | (WxDxH) | 800 x 300 x 501 mm | 800 x 300 x 520 mm | |

| Weight | 28 kg | 23 kg | ||

| Rotation Table Size | 200 mm | 200 mm | ||

| Rotation Table Weight Limit | 36 kg | 36 kg | ||