KTEC Racing, a leading UK-based performance parts and tuning company, specialises in high-performance upgrades for Renault Sport models, including the Megane, Clio, and Twingo. Operating for nearly two decades, KTEC Racing offers a comprehensive range of services, from standard interval servicing to advanced race car preparation, and provides top-tier products from renowned brands. Known for their innovation, quality, and customer-centric approach, KTEC Racing stands out with their expert team, cutting-edge technology, and commitment to excellence, making them the preferred choice for automotive performance enthusiasts worldwide.

KTEC Racing delivers high-performance automotive solutions through a range of specialised services and products. Their operations encompass standard interval servicing, race car preparation, ECU remapping, suspension upgrades, and advanced braking systems, all tailored to enhance Renault Sport models like the Megane, Clio, and Twingo. The company also offers a diverse selection of high-quality products, including bodywork, engines, exhausts, and safety equipment, sourced from trusted brands such as Airtec Motorsport and Wagner Tuning.

The Integration of Scantech 3D Scanning Technology

The integration of the SIMSCAN handheld 3D scanner has revolutionised KTEC’s operations by enabling them to collaborate with manufacturers worldwide. The introduction of 3D scanning technology marks a significant improvement over traditional measurement methods. Previously, measuring a part for design involved extensive manual drawing, which was not only time-consuming but also prone to human error. With 3D Scantech 3D scanning technology, KTEC no longer spends excessive time drafting parts manually. The precision of the SIMSCAN minimises the risk of errors, ensuring that components are crafted accurately from the outset. This advancement translates into reliable, high-quality output while drastically reducing the potential for costly mistakes.

KTEC 3D Scanning Projects

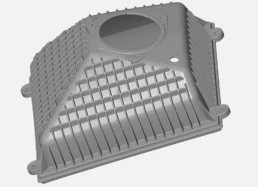

Megane 4RS KTR Intake

By utilising the Scantech 3D scanner, KTEC captured the general shape of the OEM design. They then used SolidWorks to fully recreate and tweak the design by removing interior pieces. This revised CAD model was passed on to the manufacturer, who produced the new intake. By utilising SolidWorks flow simulations, KTEC confirmed that the new design maintained the original airflow, ensuring peak performance.

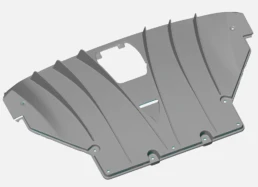

Megane 4RS Bonnet and Diffuser

On their Megane 4RS demo car, KTEC scanned the bonnet and diffuser. These scans will be used to create CNC aluminium parts. KTEC ensured that crucial mountings were captured at a high resolution.

Scanning Small Components

The SIMSCAN flawlessly captures small objects, such as a gloss black waste-gate cover or intricate details within larger parts. For example, the Clio V6 airbox scan ensured detailed and tolerance-accurate data for 3D printing, resulting in a high-quality end product.

Large Development Work

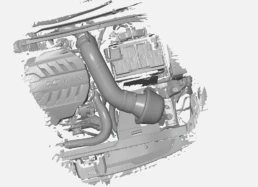

For large projects, the scanner is indispensable since it allows KTEC to scan entire engine bays or car corners rapidly and accurately, without the need to keep multiple vehicles on-site. Examples include:

-

Hyundai i30n: KTEC captured the engine bay air intake, which was then used by the manufacturer to create a perfectly fitting large air intake system for increased power gains.

-

Alpine A110s: Continuous work on this project involves scanning the engine bay and intake system for a high-flow induction kit and upgraded charge cooler.