If you’ve never incorporated 3D scanning into your in-house projects, it may sound like a complex topic.

Whilst there are intricacies involved in the process of capturing good quality 3D scan data, it isn’t as complicated as you may think it initially sounds and it is relatively simple to include within your design, engineering, or manufacturing processes.

We’ve put together an explanation of how 3D scanning works to help explain how 3D scanning – and scanning data – can help support your projects; whilst also providing guidance on what to look for when deciding how to choose the best scanner for your needs.

In absolute basic terms, 3D scanning involves capturing many images of an object with a laser and fusing them together to develop a three-dimensional image of the object. It’s not only shape that is captured, but a professional 3D scanner will also record surface details, colours and textures.

Understanding the process of 3D scanning

The most common type of 3D scanner utilises laser technology. The laser is shone onto the object being scanned, which is then reflected back to the scanning equipment. The scanner uses this data to calculate the object’s size and shape using both the angles of the reflected light and the distance between the scanner and the object. Transparent or extremely shiny surfaces can be challenging to capture due to the effect the surface has on the light of the laser; a laser will shine through a transparent surface and will bounce back off shiny surfaces but some of the more advanced systems incorporate software and optics which enable them to compensate for the more difficult surfaces.

Once the 3D scanning data has been collected, it needs to be put through 3D scanning software in order to process the captured data in order to replicate the scanned object.

Supporting your 3D scanning projects

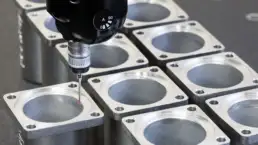

There are also several different accessories that can be added to a 3D scanner to improve certain aspects of its functionality. For example, probes are available for capturing data on an extremely small scale, such as holes or slots in objects, extended cables can be used to assist with larger projects and photogrammetry can be added where very large objects are being scanned.

3D scanners vary in their capabilities, but by their very nature, precision, size of scanning area and speed of data capture are the key features of an excellent scanner. Other important aspects that determine whether a 3D scanning device is right for you include:

-

Portability – do you have challenging environments to scan? Portability might be key to your scanner selection process

-

Flexibility – depending on your 3D scanning needs, you may require a scanner which is as fast as it is accurate

-

Multiple scanning functions – with an array of different applications and objects to scan, you might require a device that incorporates a range of different scanning modes from deep hole scanning to large area scanning using photogrammetry.