“We rely on scans taken by T3DMC to capture our artisans’ work. And once converted to 3D CAD data, it allows us to produce components efficiently and cost effectively”

Aston Martin is a brand that requires no introduction. A stunning example of British manufacturing, its sports cars were made famous across the world by the 007 spy series. However, today the brand stands for exceptional design, creativity and performance. The T3DMC team has recently provided 3D measurement systems for a unique Aston Martin re-design project.

CALLUM is a design and engineering company set up in 2019 by Ian Callum – a celebrated British car design engineer. Currently, CALLUM is working on a limited edition of 25 bespoke Aston Martin Vanquish cars. The vehicles are fully endorsed by the Aston Martin brand. These models are refined using new materials, high precision technologies and fresh inspiration, for the ultimate in automotive performance and luxury.

Bespoke automotive design

The new Vanquish 25 by CALLUM will be enhanced by a series of over 100 focused refinements. Some of these changes will be more subtle and nuanced, some more substantial. The aim is to sharpen the outline and make the Vanquish 25 the Grand Tourer for the 2020s.

To turn these innovations into reality, CALLUM first needed an accurate 3D scan of the interior and exterior of the Vanquish. However, existing portable laser scanner technology was not up to the quality and standard CALLUM required for such a crafted quality product as the Vanquish 25.

Although using a portable scanner offered convenience, the model that CALLUM initially used did not cover large scanning areas. The resulting overall accuracy was therefore insufficient for the company’s design needs.

The solution – the KSCAN 3D scanner

CALLUM got in touch with T3DMC looking for a 3D scanner that was capable of providing high quality 3D results in real time. After discussing the project with the customer, Adam Stanley, managing director at T3DMC, recommended the KSCAN scanner.

“The engineers at CALLUM explained that they were struggling with measuring local regions of the vehicle whilst keeping the relationship relative to other areas of the vehicle. They wanted to achieve that without spending a long time 3D scanning the entire car which they had attempted but had built in large unquantified inaccuracies.“

“Hearing this, we knew instantly that KSCAN was the right system for the job. The KSCAN portable 3D scanning system was developed with integrated photogrammetry, a highly accurate global measurement system, as part of the scanner, making it perfect for medium to large-scale projects. It is this combination of technologies that truly makes the KSCAN an outstanding system with incredible accuracy capability.”

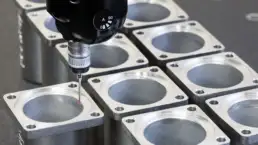

The KSCAN boasts high resolution, a 600mm scanning area and multiple scanning modes for flexibility. This enables scanning of larger sized objects, quickly; the increased depth of field compared to similar systems means that tricky to reach measurements like the interior of the vehicle, can be captured with ease. Hard geometric features can be captured during the measurement process, which allows a stable alignment to be created across the entire vehicle.

The KSCAN is a powerful handheld system that uses dual lasers, photogrammetry and can be used with the KSCAN probe for those hard to reach areas.

For this project the interior and the exterior scan were done using the same frame of reference; hard geometric features in the chassis. This accurately positioned the exterior relative to the interior without the need for lengthy and complicated post processing. In addition, the KSCAN has dual measurement volume capabilities. This means it can be used to capture large areas and ultra fine detailed regions, like clips, levers and bevels, within the same project.

Unlocking the power of photogrammetry