CASTING & FOUNDRY

We have over 20 years of experience in providing 3D scanning services for the Casting & Foundry industry. We’ve supported some of the largest and most successful foundries in the sand, die and investment casting sectors and recognise that although every project is different, our customers share common goals and challenges – they need to be able to deliver products of the highest quality and accuracy, quickly and cost effectively.

To help customers achieve these goals, our friendly team offers extensive quality & inspection services and metrology equipment which cover every aspect of casting and foundry operations, from simulation and verification to tool try out and production control. Consistent results and total quality assurance are at the core of all of our solutions.

We take the time to learn about your challenges and only then demonstrate 3D solutions that perfectly suit your requirements. Our goal is to help you achieve significant time savings for every process and gain the competitive edge in your market.

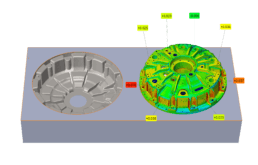

With high scanning speeds, our 3D scanning systems evaluate model and pattern plates rapidly and reliably, making it possible to detect and correct errors before they lead to lost or delayed production. This gives our customers a distinct competitive advantage, allowing them to offer shorter lead times and keener pricing. Our solutions provide:

- Full-field shape and dimension inspection

- Compensation of warpage and shrinkage

- Verification of milling results

- Change management and maintenance

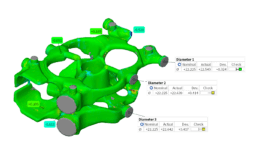

Our portable 3D measurement technologies make easy work of inspecting large components either at T3DMC HQ or at our customers premises. Quality control and inspection processes are more efficient and cost-effective than ever, whether for design verification, tool and casting prototyping, validation of a series production tools, accurate measurements of sand cores, or tool wear analysis. You will benefit from:

- Targeted tool correction

- Assembly analysis

- Fitting of mold halves, core allowance and sliders

- Wear analysis

In the early stages of product testing it is often necessary to measure distortions encountered during normal usage, or the results of wear during phases of intensive use. With T3DMC expertise by your side these measurements can be made easily, quickly and accurately, ensuring that our customers perform to specification throughout their whole working lives. We can support you with:

- First article inspection and production quality assurance

- Shrinkage, warpage and allowance control

- Material thickness analysis

- Optimized CNC machining