“When T3DMC moved in right next to us, we immediately realised that this was both fortunate and convenient,” said Gary Beech, Metrology Manager at Shropshire-based Grainger & Worrall. “We were impressed by the capabilities, flexibility and responsiveness of T3DMC and we very soon started to use the company’s inspection services to supplement our own in-house portable scanner and 3D modelling and measurement capabilities.”

A world-leader in castings, Grainger & Worrall is a driving force in the move toward lighter and more efficient means of propulsion in the automotive sector. The company’s head office, development centre and production facilities are located on the Stanmore Business Park in Bridgnorth, adjacent to 3D inspection specialist T3DMC. Over the years, the two companies have built a strong working relationship.

Grainger & Worrall principally develops and manufactures high-end automotive powertrain units and gearboxes for motorsport, commercial and defence applications. The company also works with automotive body in white (BIW) structures, which are preferred in many applications because they reduce weight by as much as 30% compared with steel components and do so without compromising on strength.

Delivering 3D scanning precision for manufacturers

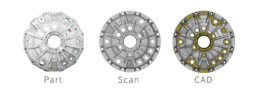

To help it deliver precision components manufactured to the tight tolerances that its customers expect, Grainger & Worrall uses its own in-house 3D scanning measurement systems. However, having access to alternative 3D measurement technologies can be very advantageous for applications that include highly reflective machined parts, and repeat part accuracy.

“We have always had in-house 3D scanners, but for certain challenging projects, we need additional engineering support” explained Gary Beech, Metrology Manager at Grainger & Worrall. “T3DMC has the latest in technology to hand, and their team is expert in capturing data from even the most complex components for high-end vehicles and aerospace applications.”

The solution – T3DMCs temperature-controlled measurement room

T3DMC provides highly accurate 3D scanning services through the operation of the GOM ATOS ScanBox 6130; the largest Independent Optical Measurement Machine in the UK. Housed in a temperature stable measurement room, this system is operated by a specialist team with decades of experience in programming and operating the equipment. T3DMC focuses in delivering results that satisfy the most demanding of requirements. T3DMC has used this 3d scanning equipment extensively in its work for Grainger & Worrall for reverse engineering and inspection alike.

“Working with T3DMC has decreased our time to market and helped us in our challenge to streamline our development and production processes,” added Gary. “We’ve come to see T3DMC as an extension of our own metrology department that allows us to handle even the most challenging metrology projects quickly and cost effectively.”

“The T3DMC team is always responsive and its technical knowledge as well as its positive approach to problem solving are second to none. The quality of work is impressive, and the team has proved able to tackle any kind of job we throw at it!”

Thanks to T3DMC, Grainger & Worrall is now able to get the validated product to its customers faster than its competition. This was recently demonstrated by a successful project where the two companies collaborated on a very specific type of analysis needed by a prestige OEM of luxury vehicles. Contact us to learn more about how we can help your business through out 3D scanning services.

Working closely with the customer

If you have a similar, complex application that needs high quality inspection and measurement, T3DMC is the expert team to call.

Give us a call on 01746 762251 or drop us a note on info@t3dmc.com.

Other news articles

7th February 2024

Revving Up Innovation: T3DMC Becomes Prodrive’s Official 3D Scanning Partner

Explore how our 3D scanning partnership with Prodrive is accelerating advancements in motorsport and driving innovation.

29th August 2023

Preserving History With 3D Scanning Technology: The Mk2 Cockle Canoe, Operation Frankton

Preserving history with SIMSCAN. Capturing 3D data of WW2's unsung hero, Operation Frankton's Mk2 Cockle Canoe.