Empowering Digital Transformation and Innovation

We are excited to announce our partnership with Prodrive, a market leader in motorsport. As Prodrive’s official 3D scanning partner, we will facilitate success on and off site by redefining the cutting edge and driving innovation.

About Prodrive

Prodrive is a world-renowned motorsport and advanced technology enterprise recognised for its innovative engineering solutions. With roots in motorsport, Prodrive has expanded its reach to industries such as automotive, aerospace, marine, and beyond. The company’s ethos revolves around transforming the ambitious ideas of its clients into tangible realities.

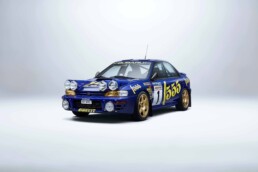

Prodrive’s success in motorsport is unparalleled, with victories across various disciplines, including World Rally titles with Subaru, Le Mans titles with Aston Martin and Ferrari, and British Touring Car Championships with BMW and Ford.

Prodrive Adopt Scantech Technologies

“With the Scantech systems we can have full visualisation straight into our CAD in hours. This is something you can’t get with traditional systems.” – Paul Doe, Chief Chassis Engineer

Scantech’s systems will play a crucial role in Prodrive’s quality control process and reverse engineering applications. Prodrive is leveraging Scantech’s cutting-edge technology in the production of their Dakar rally car frames, Aston Martin race cars and the Subaru P25. The capture of 3D data across various projects enables in-depth analysis and informed decision-making regarding potential modifications before vehicle assembly proceeds. This strategic integration not only streamlines Prodrive’s workflows, but also significantly reduces costs.

“Working with T3DMC gives us access to people who really know what they are doing in the world of metrology, specifically 3D scanning. We want to make sure we are getting everything out of the equipment in the correct ways.” – Paul Doe, Chief Chassis Engineer

The TrackScan and SIMSCAN, both part of Prodrive’s arsenal, serve distinct functions. The former, with its large-scale measurement capabilities, is used to scan space frames efficiently, while the latter collects 3D data from tight, damage-prone areas such as wheel arches. These tools, together with historical data overlays, allows Prodrive to identify any damage or areas out of tolerance swiftly, reducing errors throughout the production process. Prodrive’s integration of Scantech systems has catapulted their productivity to new heights, while simultaneously refining a variety of key workflows. This integration underscores the formidable power of 3D data. In motorsport, time is of the essence, both on the racetrack and in the workshop. Prodrive has effectively harnessed this principle, ensuring every second counts.

Other news articles

29th August 2023

Preserving History With 3D Scanning Technology: The Mk2 Cockle Canoe, Operation Frankton

Preserving history with SIMSCAN. Capturing 3D data of WW2's unsung hero, Operation Frankton's Mk2 Cockle Canoe.