Metrology News have recently published a very interesting article about a German company who, by using an optical 3D measuring system by GOM, have been able to significantly accelerate the production of their injection moulding tools using CAD data.

The plastic injection moulding industry are using 3D scanning as part of their design process to reduce their process time and therefore their cost but not all manufacturers have the equipment available to help them in this way. The 3D Measurement Company (T3DMC) have a fully independent open sourced scanning facility with a range of optical and laser based scanning technology combined with over 20 years industry experience in operating, programming and optimising scanning protocols for a wide range of parts across most industries.

Our team are experts in using VMR systems and have the capability to scan your parts in house in our temperature stable facility able to accommodate parts up to 2 tonnes in weight and 3 meters in diameter or we can come to your facility where we use our portable equipment to provide accurate and repeatable data that can help you to improve your design process.

For more information, please contact us on info@t3dmc.com or give us a call on 01746 762251

Read the Metrology News article here, or below:

Oechsler is a traditional company from Bavaria, Germany, that continuously works to improve its process chains. By using an optical 3D measuring system by GOM, the plastics specialist has been able to significantly accelerate its production of injection molding tools.

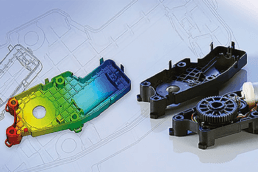

If drivers of modern cars no longer need to worry about difficult uphill starts assisted by manually pulling the parking brake, this is in part due to an invention by Oechsler AG.. In the late 1990s, the Bavarian plastics company developed an actuator for the Electronic Parking Brake (EPB), which is replacing the traditional manual brake in an increasing number of vehicles. The core of the actuator is a gearbox made of plastic. The patented design uses high-tech materials to fulfil the demanding performance requirements while maintaining a low installation weight.

Company HQ in Ansbach is one of six production sites globally, more than 400 different materials are processed, with a total volume of 6,000 tons/year. Almost 80 percent of these materials are fibre reinforced. “Such materials have a natural tendency to warp”, explains Marco Wacker, Dr.-Ing., head of technology and innovation at Oechsler and a member of the managing board. “Especially in some products like housing parts with a low wall thickness.”

The measurement of these housings with tactile systems kept causing problems. Changes that had been made to the tools were not always reflected in the measured data. “When we looked at the problem a little closer, we realised that tactile measurement took too much time, in addition to measuring only part of what we needed. On top of this tactile measurement reduces a 3D measurement to an abstract representation of binary or ternary points in a table. Then the designer has to implement the results into his 3D system”, explains Wacker. “It no longer made sense in the digital age.”

In 2012, the search for an alternative method began. The final decision was based on a bench-marking process that compared the in-house, tactile measuring systems with a CT scan (computer tomography), as well as with an optical measuring system namely GOM’s ATOS Triple Scan, which uses 3D scanning with fringe projection. The CT system and the GOM solution had prevailed in a pre-selection process.

Fringe Projection for Measurements that Take only Seconds

During the intense benchmarking process, the same housing part was measured six times with 550 data points each. In the end, the CT and the fringe projection technology were neck and neck in terms of speed and accuracy. The fact that Oechsler produces many hybrid parts (e.g. housing parts with inserts and/or lead frames) was the decisive factor in favour of the ATOS Triple Scan by GOM.

Instead of capturing individual points, the optical 3D performs a full-field scan of the entire part geometry. The result is a high-resolution point cloud.

The projected fringe pattern is recorded by two cameras. A highly detailed image consisting of millions of measuring points can be recorded within a few seconds non-contact. The GOM software computes three-dimensional object coordinates for each camera pixel. The calculated polygon mesh describes free-form surfaces and regular geometries that can then be aligned with the drawing or directly with the CAD data set in a shape and dimension analysis – the measurement is full-field. Compared with tactile measurement technology, the entire part surface can be scanned very quickly without any blind spots.

Norbert Krauß, Research & Development Project Manager at Oechsler, confirms: “The great thing about the optical system is that it shows many things at once. There is no need to think about flatness; you can see where the diameters are, and the location of connectors, contacts, and positions.”The user gets an overview of the entire part at a glance, instead of just a few abstract points like with tactile measurement. This makes it a lot easier to perform several corrections in one step.

“Previously, we needed to approach tool modifications step by step in an iterative process to avoid build-up welding,” explains Wacker. “Now we can see the entire component, and that gives us a lot more confidence. We’ve been able to significantly reduce the number of iterations.”

Simulation and Measuring System Complement Each Other

After a part has been constructed, a quote needs to be calculated. If Oechsler gets green light from the customer, then the tool is verified in the tool making department, and a flow simulation is calculated in an attached simulation department using the Moldflow Software.

The simulation delivers excellent results for most of the materials that Oechsler uses, including the warp prediction. “This is why we build our tools with a slight warp now,” Wacker explains. “And to enable us to become better and better over time, we created an internal control loop.”

At first, the simulation expert enters process parameters into the simulation system based on his long years of experience. The operator at the injection moulding machine accepts the data, modifies parameters if necessary, or makes the tool based on his own experience. In any case, he measures the plastic product using the GOM system and returns the results to the simulation. Wacker: “On one hand, this gives the simulation expert feedback on the quality of his prediction. On the other, he learns how the process has to be adjusted according to the technical experts. Based on this feedback, he can then improve his model again to incorporate such insights into the next simulation.” Birgit Hauf, a member of the R&D department and in charge of the GOM system, adds: “Step by step, we are building experience like a library. In the long run, this helps us to simplify repetitive measurement tasks. GOM is a key element in this internal control loop.”

Construction, Tool Making, and Production departments then discuss possible modifications based on the measurement results. Birgit Hauf: “In cooperation with the tool maker, I create a correction report that is implemented in CAD. The tool is corrected and re-sampled.” This control loop is repeated until the desired accuracy has been achieved.

Krauß (Head of R&D): “Thanks to the improved information that the GOM system delivers, it now takes only three loops on average for new parts. For parts that frequently recur in similar shapes, we only need one large and one smaller loop. With tactile measurement, it took a lot of effort and multiple iterative loops to slowly approach the final tool contour.” Board member Marco Wacker adds: ”Our goal is one loop.”

3D Scanner also Excels in Materials Comparison

Oechsler is also using the ATOS Triple Scan to compare materials. “A PBT GF 30 from one manufacturer doesn’t necessarily behave the same way as a PBT GF 30 from another manufacturer,” says Wacker. The measuring system allows to determine quickly during the sampling stage whether a material behaves similarly to the reference material and which adjustments may be required. With housing parts, the critical point is often at the connector, where the wall thickness is lowest. “There can be considerable variation between manufacturers in the tenths range, which we may not be able to compensate by with parameter changes,” Wacker describes the problem. “As a last resort, we can only do a tool correction.” This can be prevented by sampling several alternative materials at an early stage during tool release. The GOM system helps to reduce the effort required and quickly delivers results. This is a critical factor especially during the sampling stage of a project.

Free Software for Comprehensive Evaluation

Oechsler uses the free-of-charge GOM Inspect software to evaluate and visualize the measurement data. The software package enables editing and evaluation of 3D CAD data from fringe scanners, laser scanners, CTs, and other sources. This free software can also be used as a 3D viewer for collaborative evaluation of measurement results.

Birgit Hauf: “The GOM Inspect software isn’t restricted to the GOM system. We can use it to do any kind of evaluation, such as comparing CAD data, querying dimensions, doing 2D sections. It’s a very versatile tool.” Therefore, not only the departments directly involved in measurement, but also trainees and sometimes even the Oechsler management board use this software. Wacker: “Just out of curiosity, I used GOM Inspect to do an evaluation by myself.”

Automated Measurement as a Future Priority

About 80 tools were built at Oechsler in the past year, and 35 of these tools have been validated with the GOM system. The responsibility for the entire project is still with the R&D department. However, board member Marco Wacker plans to transfer them to the technical departments step by step. By now, the new technology has found broad acceptance in the departments. R&D project manager Krauß: “We have developed the process to a stage that the departments can easily work with it.”

This would be another step towards Marco Wacker’s goal: “In the midterm, we plan to semi-automate the measurement with GOM, and maybe go fully automated at some point. This would give us considerable time and process-related benefits for the company.”

For more information: www.gom.com.

Recent news posts

Related news articles

7th February 2024

Revving Up Innovation: T3DMC Becomes Prodrive’s Official 3D Scanning Partner

Explore how our 3D scanning partnership with Prodrive is accelerating advancements in motorsport and driving innovation.

29th August 2023

Preserving History With 3D Scanning Technology: The Mk2 Cockle Canoe, Operation Frankton

Preserving history with SIMSCAN. Capturing 3D data of WW2's unsung hero, Operation Frankton's Mk2 Cockle Canoe.