Merging the digital world with the physical world, Porsche Production 4.0 is the natural evolution of the current production system. Augmented reality is being used to discover precise information about individual components quickly in Porsche’s quality centre. Work steps can be displayed on a tablet with added computer-generated information. Even minor discrepancies from the standard are diagnosed rapidly making it clear to see where body part fit issues occur.

Quality control measuring

Optical quality control measuring is used to check the body parts quickly and accurately. Every component is fully digitalised and measured in three dimensions. The entire component is extensively plotted in a high resolution cloud, which has been recorded by a laser scan. Up to 16 million points are recorded by scan. Anomalies between each body point and the as-designed 3D CAD data can be determined in a minimal amount of time. Using the digitised data anomalies are also visualised exactly by 3D representation.

Conventional templates are no longer required for correct bolt positioning – instead, a laser system has been put in its place. The projected laser image allows the positions of the bolts to be adjusted quickly, dispensing the time necessary and cost intensive production of new bolt templates.

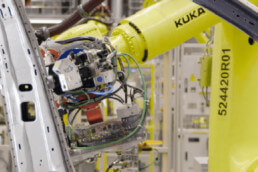

The Panamera side-panel frame is produced from aluminium rather than steel; a line laser scanning sensor guides the automated roll hemming process implemented combing the soft aluminium alloy with hot-formed steel to optimum effect.

Does your business have a need for quality control services? Contact us to discuss your project needs.

Recent news posts

Related news articles

7th February 2024

Revving Up Innovation: T3DMC Becomes Prodrive’s Official 3D Scanning Partner

Explore how our 3D scanning partnership with Prodrive is accelerating advancements in motorsport and driving innovation.

29th August 2023

3D Scanning,Portable 3D Scanning

Preserving History With 3D Scanning Technology: The Mk2 Cockle Canoe, Operation Frankton

Preserving history with SIMSCAN. Capturing 3D data of WW2's unsung hero, Operation Frankton's Mk2 Cockle Canoe.