“T3DMC provide us with tailored and responsive business support… 3D scanning offers us accuracy, speed and convenience, enabling the capture of complex geometry which is difficult to replicate. We have trust and confidence in the data and model supplied by T3DMC; we know that if it fits the tooling, it will fit the final piece.”

In today’s competitive market, it is crucial for businesses to be able to develop new products quickly and efficiently, and 3D scanners are changing the way products are designed and manufactured. 3D scanning technology allows for a quicker, more accurate way to create 3D models of objects which is leading to faster production times and reduced costs for companies that adopt 3D scanning into their workflow.

This technology is revolutionising the way products are designed and created, and is changing the manufacturing industry in a big way.

One such company, Forma Moulds, relies on 3D scanning technology to create its products.

Forma Moulds specialises in silicone injection moulding for a variety of industries, including food, candles, cosmetics and more. A forward-thinking team of industrial designers and engineers, they offer a range of services that will take a concept through design development to market ready production.

The Power of 3D scanning for Product Design & Development

3D scanning is an essential part of Forma Moulds’ design and development process. With their ability to quickly capture data, 3D scanners enable Forma Moulds’ design team to produce high-quality silicone protective covers and accessories with minimal time investment required during the production process.

In addition to 3D scanning, Forma Moulds uses 3D printing to create prototypes and finished products, allowing for the creation of complex shapes that would be difficult or impossible to create using traditional manufacturing methods.

Design and Manufacture of Specialist Protective Covers

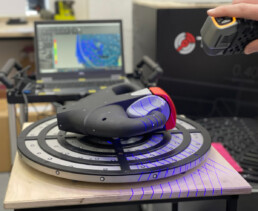

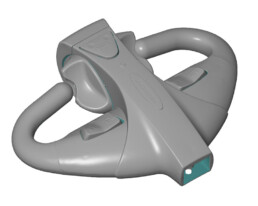

Forma Moulds approached T3DMC to assist with the 3D scanning of intricate forklift truck handles to enable the design and manufacture of specialist protective silicone covers for these parts.

The forklifts are operated in an industrial environment where contamination could potentially transfer onto the controls of the handles. The silicone cover performs two main functions; it is a vital health and safety measure to keep the handle’s controls clean and free from chemical erosion, avoiding the potential hazard of triggering automatic movement and reducing accident risk, and it prolongs the life of the part and vastly decreases the requirement for costly replacements.

Portable 3D Scanning Solutions & CAD Expertise

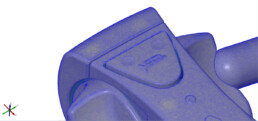

3D scanning enables the accurate capture and measurement of complex and organic shapes without the use of callipers or traditional measurement equipment, which is time-consuming and often not precise.

“The first stage of the process involved a 3D scan of the part, from which a CAD model was created by T3DMC’s specialist engineers,” says Neal Taylor, T3DMC’s Technical Director.

“This enables us to produce high quality tailored data for our clients very quickly, vastly speeding up the design development process.”

The T3DMC team utilised SIMSCAN for this project; a small but powerful, versatile handheld 3D scanner which is ideal for this type of application, providing detailed, highly accurate measurements.

Forma Moulds were able to easily invert the CAD data to create the tooling from which the protective cover can be produced, and 3D printed.

“T3DMC provide us with tailored and responsive business support. The CAD file supplied by Neal and the team for this project was ready to go straight into SolidWorks, and we could start immediately.” says Thomas Lane, Director at Forma Moulds.

“3D scanning offers us accuracy, speed and convenience, enabling the capture of complex geometry which is difficult to replicate, and we often work on projects where design drawings are not available. We have trust and confidence in the data and model supplied by T3DMC; we know that if it fits the tooling, it will fit the final piece.”

Utilising 3D scanning capability for this project offers a huge saving in terms of time, enabling Forma Moulds to design and manufacture the tooling and start the production process with an incredibly fast turnaround.

Need help with your design project?

T3DMC has extensive experience in the 3D measurement world; whether you are interested in a 3D laser scanning solution for in-house use, or you’re looking for support from our technical team at your site or ours, we can build a solution around your needs. Get in touch today.

Other news articles

7th February 2024

Revving Up Innovation: T3DMC Becomes Prodrive’s Official 3D Scanning Partner

Explore how our 3D scanning partnership with Prodrive is accelerating advancements in motorsport and driving innovation.

29th August 2023

Preserving History With 3D Scanning Technology: The Mk2 Cockle Canoe, Operation Frankton

Preserving history with SIMSCAN. Capturing 3D data of WW2's unsung hero, Operation Frankton's Mk2 Cockle Canoe.