Quality Digest published a great article this week about how GE Appliances (GEA) utilise 3D metrology tools including ATOS 3D scanners, TRITOP photogrammetry and ScanBox for high quality engineering solutions.

The article discusses how GEA have been making high quality appliances from ovens to water heaters for over 125 years in the US and are renowned for the longevity of their products, thanks to their commitment to “technological innovation” and better manufacturing processes.

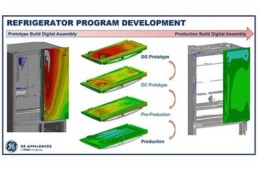

In recent years, GEA’s innovative approach have lead them to using GOM technologies – ATOS and TRIPTOP specifically. Having been introduced by a partner company, “they knew that adding 3D metrology capabilities would significantly improve their processes and efficiency” and having bought into these technologies, the director of dimensional control for GEA commented “his team was instantly able to start driving improvement. Leone views the GOM systems as more than just a stand-in for the traditional CMM. He describes ATOS as a powerful engineering tool”.

“3D scanning has really opened our minds to leveraging the power of digital data” Leone told Quality Digest. We at T3DMC urge similar companies who want to strive for better manufacturing processes to improve their products for end users, to adopt this approach.

Professional 3D Scanning from T3DMC

The 3D Measurement Company (T3DMC) own and operate a GOM ATOS ScanBox as part of the largest open source automated 3D optical scanning system in the UK and our team have over 20 years experience in complex metrology across a huge range of different components and applications. T3DMC offer an independent scanning service where we offer our customers the provision of an engineering solution using 3D Optical scanning data using the latest industry leading technology.

The T3DMC team are used to working on a wide range of complex projects across a number of different industries and this enables us to quickly identify the optimum scanning methods for your projects without the capital investment in equipment and extensive staff training. If you have a complex engineering problem where 3D Optical scanning, measurement and inspection services could potentially help then give us a call on 01746 762251 or drop us a note on info@t3dmc.com

To read the full article, go to http://www.qualitydigest.com/inside/metrology-article/redefining-product-development-using-3d-metrology-solutions-062018.html

Recent news posts

Related news articles

7th February 2024

Revving Up Innovation: T3DMC Becomes Prodrive’s Official 3D Scanning Partner

Explore how our 3D scanning partnership with Prodrive is accelerating advancements in motorsport and driving innovation.

29th August 2023

3D Scanning,Portable 3D Scanning

Preserving History With 3D Scanning Technology: The Mk2 Cockle Canoe, Operation Frankton

Preserving history with SIMSCAN. Capturing 3D data of WW2's unsung hero, Operation Frankton's Mk2 Cockle Canoe.