We are proud to house the UK’s largest automated optical coordinate measurement machine, capable of measuring 3m diameter and 2 tonne in weight. We see from our own expanding customer base, the importance of automation in the cmm inspection process and we can see more of it in this Metrology News article, below. To see how our automated measurement services can speed up your inspection process please get in touch.

Full story below, from Keith Mills @ Metrology News:

“The automotive industry has always led most other industries in the implementation of new advanced manufacturing technology due to ever shortening product life cycles times. One technology critical to the delivery of quality automotive products, with the necessitated increasing of productivity and lowering of costs, is 3D metrology.

Recent automotive industry trends have seen the transition from off-line quality control inspection to near-line or in-line production measurements providing an increased sampling frequency and quicker inspection times.

The most advanced automotive manufacturers are now automating inspection and integrating the created inspection data within its total product management systems allowing the generated actionable data to provide intelligent manufacturing decisions real-time ensuring ongoing production quality is maintained.

The dual-arm coordinate measuring machine (CMM inspection), that has been ever present in car plants for more than 30 years, is being replaced by faster optical scanning solutions which are also becoming fully automated allowing car body measurements to be completed in just minutes as opposed to the many hours required by the traditional CMM. Software is also playing an increasing role in automotive metrology with simulated virtual assembly using actual measured data from parallel inspection cells. For decades the CMM has performed inspection checks on sample parts to provide a high level overview of product quality and was available to be involved in specific quality related issues.

Fast inspection process

Fast in-process gauging was used to provide process control albeit offering limited 3D metrology data necessary to solve problems upon ‘flagging’ of a quality related issue. Past inspection planning was also typically based upon critical feature points only. New metrology technology, in particular optical solutions, have evolved to the point that today they can rapidly provide accurate 3D part metrology data, not just for dimensions, but also the complete form of complex geometry parts. These system, utilising the same industrial robots used in the welding line, are capable to be installed directly into the production line replacing both the off-line CMM and in-process gauging stations. Hexagon Manufacturing Intelligence, has a long track record in delivering measurement systems to the automotive industry, and has developed its 360° SIMS robotic 3D Metrology system for automotive plant process control. The 360° SIMS end-of-line body-in-white gauging station allows measuring the body’s exterior and interior areas and can also be adapted to other measurement tasks such as underbody measurement, closure measurement, etc.

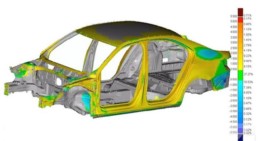

Measured data is presented using a variety of powerful analysis tools including rich colour-maps, visual SPC, comparisons, trend charts for large data sets and ‘video of the day’ reports. Analysis of measurement results such as surface geometries, edge lines, character lines and cross sections makes it easier for production personnel to understand the main cause of quality issues and quickly resolve them.

The system’s fusing of innovative 3D area-measurement sensors, mounted on industrial robots, powered by advanced software allow customers to develop new, more effective measuring processes. The fast, rich and actionable data solution enables automotive manufacturers and tie 1 suppliers to apply fully-automated dimensional quality processes for sheet metal and body assembly inspections. With 360° SIMS, both production and quality personnel gain near real-time access to full surface and geometry inspection information as well as critical feature and point measurements directly on the production floor. System functionality and benefits extend beyond the boundaries of the measuring station and the single inspected part; the 360° SIMS system offers multi-part process control analysis and reporting functionality, as well as integration with Q-DAS SPC software and other functions designed to support smart corrective actions.

Once the body-in-white and closure parts have been automatically measured in their respective lines, it’s possible to use software tools to load these separate measurement results into the shared car coordinate system. In this virtual assembly environment the point cloud of all parts can be visualised and compared to CAD and studies conducted focused on predictive assembly quality and fit and finish including virtual flush and gap or seal gap analyses. 360° SIMS represents a major step towards the digital factory.”

Learn more about CMM Inspection

Looking for more information on cmm inspection? Read more on our website.

Discover more from Metrology News here.

Recent news posts

Related news articles

7th February 2024

Revving Up Innovation: T3DMC Becomes Prodrive’s Official 3D Scanning Partner

Explore how our 3D scanning partnership with Prodrive is accelerating advancements in motorsport and driving innovation.

29th August 2023

3D Scanning,Portable 3D Scanning

Preserving History With 3D Scanning Technology: The Mk2 Cockle Canoe, Operation Frankton

Preserving history with SIMSCAN. Capturing 3D data of WW2's unsung hero, Operation Frankton's Mk2 Cockle Canoe.